HZS100\120 Stationary Concrete Batch Plant

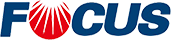

Aggregate feeding method: Conveyor belt

Aggregate bins volume: 4x16m³

Additive weighing: 2x3000kg ±2%

Productivity: 120m³/h

Total power: 160KW

Total weight: 71T

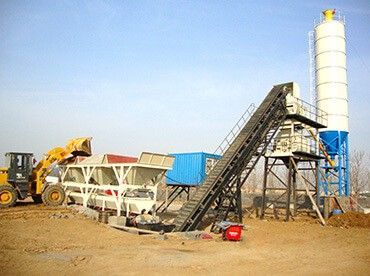

Description

This concrete batching plant is Focus’ newly developed products on its many years' experience of producing concrete mixing equipments combined with international top technology and advantages and techniques of advanced machine types both in China and abroad in recent years. It is the only product in the same field in China that achieves domestic leading level in general index and achieves international advanced level in such aspects as high productivity, noise control, environmental protection, etc. Thus it was chosen as one of the NATIONAL KEY NEW PRODUCTS in 2006.

Main features of this ready-mix concrete plant:

01

Concrete batcher can be designed as underground, partially underground or fully-above ground, 3-6 hoppers are pneumatically controlled by computer with fast and accurate instruct, whole job can be done in separate or accumulative models.

02

Aggregate belt conveyor is truss-framed for easy assembly, inclination angle is normally less than 20 degrees, however, it can be up to 45°by adopting through(groovy) belt when the ground area is limited.

03

Dust collection system mainly aims at dealing with dust generated in the process of loading the mixer and pumping powder into the powder tank, all in closed state.

04

Adopting twin-shaft compulsory concrete mixer, it mixes evenly and rapidly, achieving good mixing effect for all kinds of dry, semi-dry and plastic concrete.

05

UPS, stable performance Siemens PLC, high speed and precision weighing unit module combined with our professional control and monitoring software.

06

Full automatic and easy operated production process of material measurement, transfer, mixing and discharging.

07

Compact-structured planetary gear was adopted to ensure smooth, speedy and efficient transmission.

08

Three-point suspension sensors equipped to guarantee accurate and fast powder and liquid weighing.

09

Heating system and ice plant could be adopted into this plant in severely cold and hot environment.

Parameter

| Type | HZS120 |

| Productivity in theory | 120m³/h |

| Mixer | JS2000 |

| Total power | 160KW |

| Maximum aggregate diameter | 80mm |

| Aggregate feeding method | Conveyor belt |

| Aggregate bins volume | 4x16m³ |

| Aggregate weighing | 2X3000kg ±2% |

| Cement weighing | 1200kg ±1% |

| Fly-ash weighing | 600kg ±1% |

| Water weighing | 600kg ±1% |

| Additive weighing | 50kg ±1% |

| Discharging height | 3.8m |

| Overall dimension(during operating) (LXWXH) | 44mX18mX12.7m |

| Total weight | 71T |

| Control | Fully automatic central plus manual control |

| Cement silo(optional) | On request |

| Cement screw(optional) | On request |

Be Noted:

1. Please ask detailed configuration from our sales reps;

2. The power figure doesn't include the power of cement silo and screw;

3. Non-standard design could be made according to clients' demand;

4. The above-mentioned data could be changed due to the technical&design upgrade, please check the updated parameter when purchasing.

-

HZS25 Compact Concrete Batch Plant

HZS25 Compact Concrete Batch Plant

view detail -

HZS60 Stationary Concrete Batch Plant

HZS60 Stationary Concrete Batch Plant

view detail -

HZS90 Stationary Concrete Batch Plant

HZS90 Stationary Concrete Batch Plant

view detail -

YHZS25 Mobile Concrete Batching Plant

YHZS25 Mobile Concrete Batching Plant

view detail -

YHZS60 Mobile Concrete Batching Plant

YHZS60 Mobile Concrete Batching Plant

view detail -

YHZS100 Mobile Concrete Batching Plant

YHZS100 Mobile Concrete Batching Plant

view detail -

Super-Mobile Asphalt Mixing Plant

Super-Mobile Asphalt Mixing Plant

view detail -

Asphalt Drum Mixing Plant

Asphalt Drum Mixing Plant

view detail -

Asphalt Batch Mixing Plant LB Series

Asphalt Batch Mixing Plant LB Series

view detail

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.