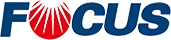

HZS90 Stationary Concrete Batch Plant

Maximum aggregate diameter: 80mm

Aggregate feeding method: Conveyor belt

Aggregate bins volume: 4x12m³

Additive weighing: 4000kg ±2%

Productivity: 90m³/h

Total power: 145KW

Total weight: 60T

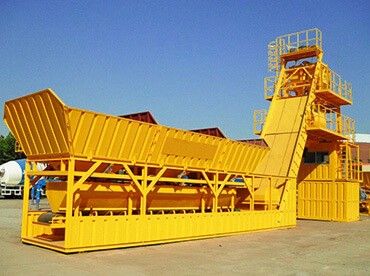

This ready-mixed concrete plant adopts JS1500 twin-shaft concrete mixer or Original SICOMA mixer, multi sealed shaft end technology. Modular design structure makes fast and convenient assembling and debugging, safe, comfortable and reliable operation with homogeneous and efficient mixing effect. It is the ideal concrete mixing plant for construction projects, power station, roads, harbor, bridge, airport, large precast products plant and commercial concrete factories.

Main features of this concrete batching plant:

Good quality material, rational design: Steel structure is made by standard steel production of large section, fast disassembly and convenient transportation; The concrete mix plant layout is flexible, covers an maximum optimization area.

Superior environmental performance: This concrete batch plant adopts closed structure, with dust removal system in the mixer tower. All belt conveyor are equipped with polyurethane sweeper, big ones are also provided with a water spray cleaning device to avoid material sticking.

Precise measurement system: Measurement of all materials (aggregate, cement, fly ash, water and liquid additive) are scaled in electronic measurement independently.

Wear-resisting design: Wear resistant design for finished concrete product hopper, aggregate collection hopper, belt machine head cover, main part is provided with a replaceable lining plate.

High quality and reliable mixer: Double horizontal shaft design, SICOMA technology, mixing rapidly and high productivity.

Suitable for different environment: Heating system and ice plant could be adopted into this plant in severely cold and hot places.

Twin-shaft FOCUS mixer is famous for its high efficiency, lower energy consumption, durable and heavy duty performance.

Heating system and ice plant could be adopted into this plant in severely cold and hot environments.

| Type | HZS90 |

| Productivity in theory | 90m³/h |

| Mixer | JS1500 |

| Total power | 145KW |

| Maximum aggregate diameter | 80mm |

| Aggregate feeding method | Conveyor belt |

| Aggregate bins volume | 4x12m³ |

| Aggregate weighing | 4000kg ±2% |

| Cement weighing | 1000kg ±1% |

| Fly-ash weighing | 400kg ±1% |

| Water weighing | 400kg ±1% |

| Additive weighing | 40kg ±1% |

| Discharging height | 3.8m-4.1m |

|

Overall dimension(during operating) (LXWXH) |

38mX16mX12.7m |

| Total weight | 60T |

| Control | Fully automatic central plus manual control |

| Cement silo(optional) | On request |

| Cement screw(optional) | On request |

Be noted:

1. Please ask detailed configuration from our sales reps;

2. The power figure doesn't include the power of cement silo and screw;

3. Non-standard design could be made according to clients' demand;

4. The above-mentioned data could be changed due to the technical&design upgrade, please check the updated parameter when purchasing.

HZS75 Compact Concrete Batch Plant

With JS1500 double shaft compulsory horizontal concrete mixer as model HZS90, hoist h...

view detail

HZS90 Stationary Concrete Batch Plant

This ready-mixed concrete plant adopts JS1500 twin-shaft concrete mixer or Original S...

view detail

YHZS75 Mobile Concrete Batching Plant

JS1500 twin-shaft concrete mixer is adopted in this series, With a homogeneous good m...

view detail

Foundation Free Concrete Batching Plant

FOCUS foundation-free concrete batching plant, also known as base-free plants, is an ...

view detail

Drum Concrete Mixer With Pump

Adopting proximity switch in hydraulic cylinder to change direction with non-touch.

view detail

Trailer Pump With Diesel Engine

Open hydraulic system with tri-pump and two circuit adopted.

view detail

Cement Bag Breaker

FOCUS cement bale breaker assembles the functions of conveying cement bags, breaking ...

view detail

FHZS60-180 Barge-mounted Concrete Batching Plant

Compared with land-based concrete batching plants, plants mounted on floating pontoon...

view detail

400T Deck Barge

Length: 35m Width: 9.0m Depth: 2.5m Rib distance: 50cm Side plate thickness: 8mm...

view detail

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.