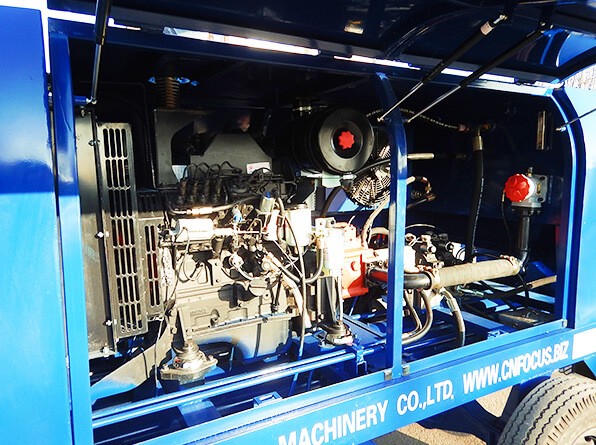

Self-walking Concrete Line Pump

Max. theo. concrete output (L./H.): 40/26 m3/h

Max.concrete pumping pressure (H. /L.): 12/7.6 MPa

Distribution valve type: S Valve

Concrete cylinder diameter×stroke: Ф180×1300 mm

Hopper capacity×feeding height: 400×1100 L×mm

Outlet diameter: Ф150 mm

FOCUS Self-walking Line Pump adopts 32HP engine/5 gears/driver's cab for driving mechanism, boosting characters as follows:

Hydraulic system

Double open hydraulic loops (pumping hydraulic circuit is independent of distributing hydraulic circuit) with two pumps, makes the whole hydraulic system much simpler. The reliability of the whole system is also much higher as well as the components’ life is prolonged greatly. This is convenient for judgeing and removing trouble.

Large valve changing direction, makes the main pumping loop quick response, small leakage, good stability, high reliability and high resist contaminative capability.

Hydraulic system has safe relief protection, at the same time, when the system pressure is over, the main oil pump cutting device makes itself be protected reliably.

Distributing hydraulic circuit adopts constant pressure pump, which can provide strong distributing pressure and economic energy control.

Cone sealing of all pipes make the pipe joints seal reliably.

The high-low pressure switch adopting cartridge valve of reduces the trouble of dismantling and installing the oil pipe.

Adopt emulsification technology of initiative and passivity recovery integration.

Mechanical system

The design of hopper and S valve and so on adopt I-DEAS software to calculate, the hopper and S valve have good rigidity to avoid the phenomenon of hopper distortion and S valve breakage.

The agitator has unique form, which separates the hydraulic motor from agitator bearing pedestal. At the same time, adopting large displacement motor ensures that the agitator moment is big enough.

Make sure the pumping is good and decline the phenomenon of pipe jam, the spectacles wear plate and cutting ring should be used in lower abrasion. FOCUS spectacles wear plate and cutting ring use high wear material, making the components’ life prolonged greatly.

Lubrication system

The hydraulic circuit will take high oil into double distributor, and then the lubricating part can obtain hydraulic oil. It ensures the lubrication of the concrete cylinder’s piston and other parts and prolongs the life of piston and other sealing knits.

Cooling system

The radiator equipment makes the working oil temperature of hydraulic system below 70℃ and makes the machine in normal status.

| Items | Units | Parameters | ||

| ZLHBTS40-12-82R | ||||

| Whole performance of machine | Max. theo. concrete output (L./H.) | m3/h | 40/26 | |

| Max.concrete pumping pressure (H. /L.) | MPa | 12/7.6 | ||

| Distribution valve type | S Valve | |||

| Concrete cylinder diameter×stroke | mm | Ф180×1300 | ||

| Hopper capacity×feeding height | L×mm | 400×1100 | ||

| Outlet diameter | mm | Ф150 | ||

| Power system | Diesel engine model | WP4G110E220 | ||

| Electrical engineering power | kW | 82 | ||

| Rotate speed | r/min | 2100 | ||

| Hydraulic system | Circuit type | Open circuit | ||

| Pumping system pressure | MPa | 31.5 | ||

| Mixing system pressure | MPa | 6-8 | ||

| Capacity of oil tank | L | 370 | ||

| Concrete delivery distance (horizontal/vertical) | m | 160/500 | ||

| Other parameters | Max. aggregate diameter | mm | Scree:30/40 | |

| Inside diameter of delivering pipe | mm | Ф125 | ||

| Dimensions:length×width×height | mm | 4800×1850×1700 | ||

| Total weight | kg | 4500 | ||

| Tractor head | 5 gears, 32HP with driver’s cab | |||

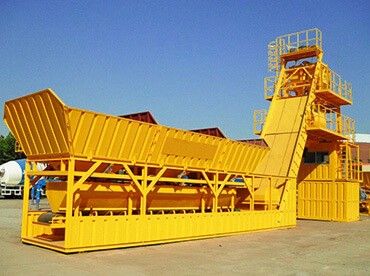

HZS75 Compact Concrete Batch Plant

With JS1500 double shaft compulsory horizontal concrete mixer as model HZS90, hoist h...

view detail

HZS90 Stationary Concrete Batch Plant

This ready-mixed concrete plant adopts JS1500 twin-shaft concrete mixer or Original S...

view detail

YHZS75 Mobile Concrete Batching Plant

JS1500 twin-shaft concrete mixer is adopted in this series, With a homogeneous good m...

view detail

Foundation Free Concrete Batching Plant

FOCUS foundation-free concrete batching plant, also known as base-free plants, is an ...

view detail

Drum Concrete Mixer With Pump

Adopting proximity switch in hydraulic cylinder to change direction with non-touch.

view detail

Trailer Pump With Diesel Engine

Open hydraulic system with tri-pump and two circuit adopted.

view detail

Cement Bag Breaker

FOCUS cement bale breaker assembles the functions of conveying cement bags, breaking ...

view detail

FHZS60-180 Barge-mounted Concrete Batching Plant

Compared with land-based concrete batching plants, plants mounted on floating pontoon...

view detail

400T Deck Barge

Length: 35m Width: 9.0m Depth: 2.5m Rib distance: 50cm Side plate thickness: 8mm...

view detail

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.